CNC Wire EDM

Precision

Repeatability

Quality

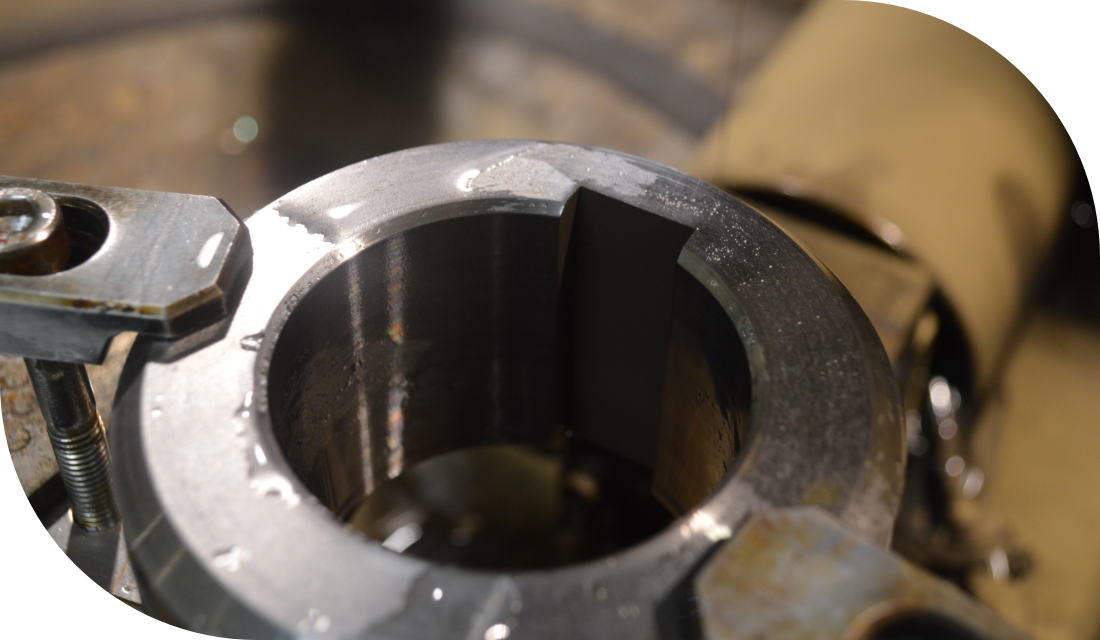

Electrical Discharge Machining

EDM electric discharge treatment - a metal treatment method based mainly on the exploitation of electrical erosion accompanying electrical discharges.

It is mainly used in the processing of specialized machine parts and other difficult-to-cut materials, as it allows for obtaining complex shapes, difficult or impossible to be machined (e.g. internal sharp corners and / or threads in hardened material or carbide), there are also no forces here cuts affecting the workpiece (although there is an impact on the outer layer, which makes further processes difficult, such as polishing). EDM machining includes EDM, anode-mechanical and electro-contact machining. The machining is carried out on cutting machines, saws or anodic-mechanical grinders, etc. It is used for the treatment of sintered carbides and for shaping and regenerating plastic working tools, e.g. forging dies, injection molds.

EDM can be broadly divided into two types: EDM and Wire Electrical Discharge Machining (WEDM). In general, the difference between these methods is the type of working electrode (in the case of WEDM it is a wire that can be wound), the energy of the discharge and the dielectric used. EDM treatment can be used for all materials with electrical conductivity greater than 10-2 S / cm.

Send your inquiry today!

office@dameks-cnc.eu

dameks@dameks-produkcja.com.pl

or call us:

+48 607 039 008

+48 601 674 458

We operate continuously

Domestic and European shipping

Take care of your business